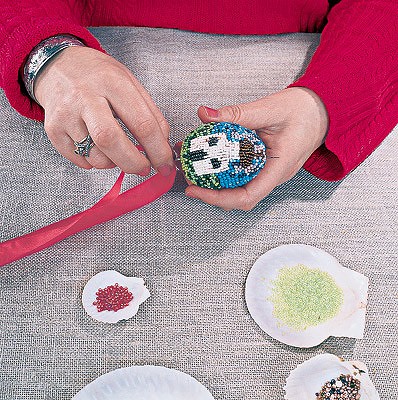

Пасхальная мозаика

Пасхальная мозаика Незаслуженно забытый способ работы с бисером мозаичное украшение пасхального яйца бисером по воску. ТВ программа Мозаика 28 04 2016 Мастер класс с Ириной

Пасхальная мозаика

Пасхальная мозаика

Как быстро освежить интерьер с помощью декоративных наклеек

Как быстро освежить интерьер с помощью декоративных наклеек

Уютный интерьер с желтыми и синими акцентами: квартира в Санкт-Петербурге для отдыха и работы

Уютный интерьер с желтыми и синими акцентами: квартира в Санкт-Петербурге для отдыха и работы

Ремонт в квартире под сдачу: 10 важных моментов

Ремонт в квартире под сдачу: 10 важных моментов

Изящные ревизии

Изящные ревизии

Выбираем робот-пылесос: 13 важных параметров и 4 полезные функции

Выбираем робот-пылесос: 13 важных параметров и 4 полезные функции

Маленькая яркая двушка для молодой хозяйки

Маленькая яркая двушка для молодой хозяйки

Основные причины, по которым течет холодильник и что делать

Основные причины, по которым течет холодильник и что делать

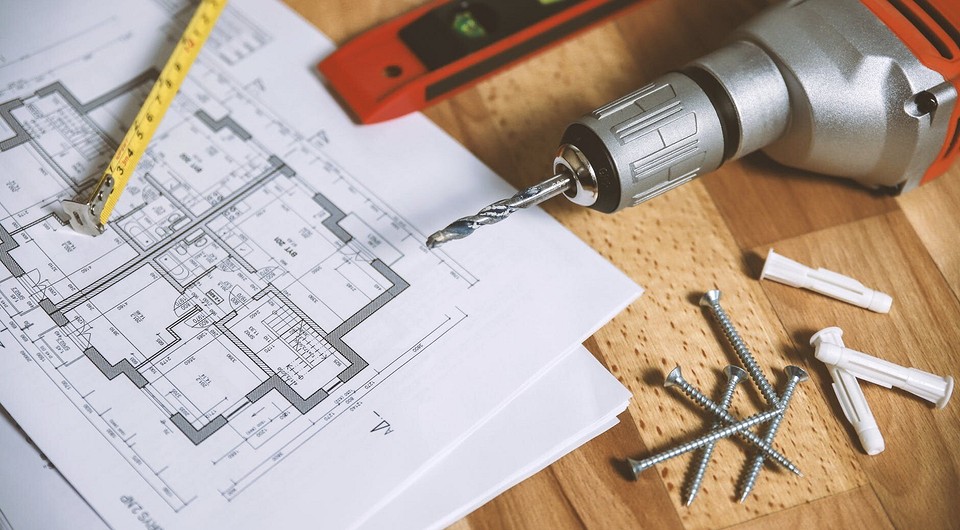

Чек-лист: 10 инструментов, которые должны быть в доме у каждого

Чек-лист: 10 инструментов, которые должны быть в доме у каждого

Модный эколофт для стилиста

Модный эколофт для стилиста

Пасхальная мозаика Незаслуженно забытый способ работы с бисером мозаичное украшение пасхального яйца бисером по воску. ТВ программа Мозаика 28 04 2016 Мастер класс с Ириной

Как быстро освежить интерьер с помощью декоративных наклеек Быстро изменить атмосферу в комнате, добавить в интерьер яркий, оригинальный акцент способны декоративные наклейки. 45+ декоративных наклеек

Уютный интерьер с желтыми и синими акцентами: квартира в Санкт-Петербурге для отдыха и работы Квартира в Северной столице предназначалась для временного пребывания во время приезда

Ремонт в квартире под сдачу: 10 важных моментов Ремонт в съемной квартире должен быть простым и практичным, но стильным. Мы расскажем, как сделатьnbsp;интерьер laquo;под сдачуraquo;,

Изящные ревизии Обзор рынка сантехнических люков устройств, обеспечивающих доступ к скрытым коммуникациям. Технологические особенности, модели, облицовка. Эскортница–сирота была в шоке, увидев себя на картине в

Выбираем робот-пылесос: 13 важных параметров и 4 полезные функции Разбираем важные критерии, такие как время беспрерывной работы и вместительность пылесборника, а также рассказываем о полезных

Маленькая яркая двушка для молодой хозяйки Площадь этой квартиры — всего 49 кв. м, но дизайнер переосмыслила планировку в соответствии с требованиями заказчицы и предложила

Основные причины, по которым течет холодильник и что делать Рассказываем, почему под холодильником может образоваться лужа и что делать в случае протечки. Не работает холодильник,

Чек-лист: 10 инструментов, которые должны быть в доме у каждого В нашей подборке — дрель-шуруповерт, отвертка, пассатижи и другие инструменты, которые могут пригодиться вам в

Модный эколофт для стилиста Дизайн двухкомнатной квартиры сочетает в себе тяжелые сварные конструкции в стиле лофт, строгие линии мебели и ярко-оранжевые шторы для настроения. СТЁГАНЫЕ